Our Products

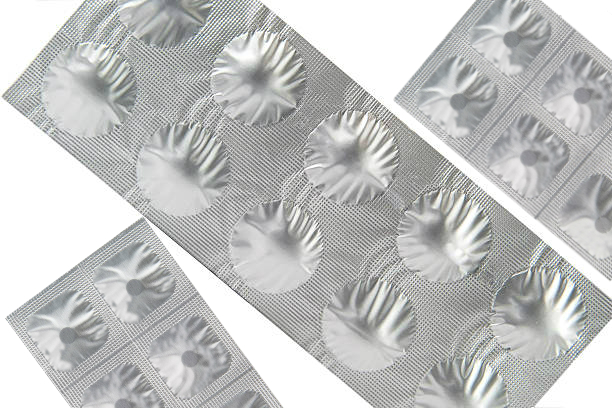

ALU ALU FOILS (Cold Form Blister Foils)

Specifications for ALU ALU Foil

| Description | Unit | Standard Specifications |

|---|---|---|

| OPA Layer | GSM | 25.99-30.51 |

| OPA Layer | Thickness | 23.0-27.0 |

| Adhesive | GSM | 3.8-4.8 |

| Aluminium Foil | GSM | 124.2-145.8 |

| Aluminium Foil | Thickness | 46.0-54.0 |

| PVC Film | GSM | 76.17-86.5 |

| PVC Film | Thickness | 56.0-63.5 |

| Total GSM | GSM | 233.96-272.41 |

| Total Thickness | Micron | 125.0-144.6 |

| Pin Hole | No./Sq. mtr | Max 0 no./SQM |

| Toxicity | - | Non Toxic |

| WVTR | gm/(m2.day) | </=0.005 |

| OTR | cc/(m2.day) | </=0.005 |

| Bonding Strength | OPA/ALU | >/=4.00 N/15MM |

| Bonding Strength | ALU/PVC | >/=3.00 N/15 MM |

| No. of Joints | No. | Max 2 per Roll |

| Core ID | mm | 76 +/- 1 mm |

BLISTER FOILS (vmch coated)

Specifications for 25 Micron Blister Foil

| Test Parameter | Unit | Standard Specifications |

|---|---|---|

| Total Weight | GSM | 72.75 +/- 8% |

| Aluminium Foil Weight | GSM | 67.75 +/- 8% |

| HSL Weight | GSM | 4.0-6.0 |

| HR Property | 180 degrees C/1.5 second | No Lifting |

| Ink Adhesion | - | No lifting |

| Printing on | Bright/Dull | Dull |

| HSL on | Bright/Dull | Bright |

| Bond Strength | Pealing (Gms/15mm) | Min 250 |

| Bond Strength | Sealing (Gms/15 mm) | Min 450 |

| Winding Direction | DSO/BSO | DSO |

| Odour Test | Conical Flask | Odour Free |

| Pin hole | Nos./sq. mtr | NIL |

| Physical Appearance | Visual | Free from any defect |

40 MICRON, 30 MICRON STRIP FOILS (LDPE laminated)

Specifications for 40 Micron Soft Aluminium Foil 37.5 Micron LDPE Film Laminated

| Test Parameter | Unit | Standard Specifications |

|---|---|---|

| Total Weight | GSM | 142.90 +/- 8% (137.47-154.33) |

| Aluminium Foil Weight | GSM | 108.40 +/- 8% (99.72-117.07) |

| Aluminium Foil Thickness | mm | 0.040 +/- 8% (0.0368-0.0432) |

| Poly Weight | GSM | 34.50 +/- 15% (29.32-39.67) |

| Ink Adhesion | Visual | Should Pass Tape Test |

| Inner Diameter of Core | mm | 76 +/-1 |

| Bursting Strength | kg/sq. cm | Min. 2.5 |

| Peel Strength | Gm/25 mm | Min. 250 Gm/25 mm |

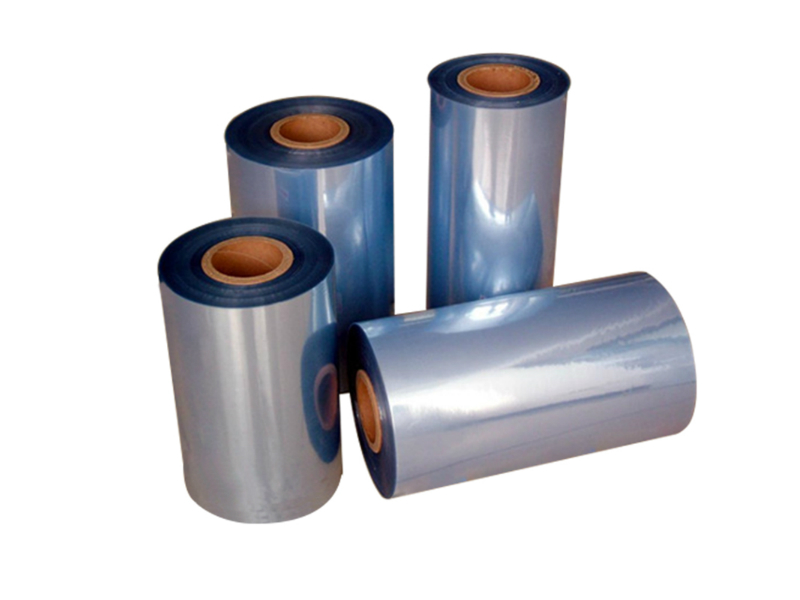

250 MICRON & 350 MICRON RIGID PVC FILMS, PVC/PVDC FILMS (CLEAR & AMBER)

Specifications for Rigid PVC FILM

| Test Parameter | Unit | Standard Specifications |

|---|---|---|

| Thickness | mm | 0.25 +/- 5% |

| Gloss @ 20 Degree | GU (%) | >/= 60 |

| Shrinkage at 140 Deg. C for 10 min | % MD | -3.0 to -6.0 |

| Shrinkage at 140 Deg. C for 10 min | % TD | +0.5 to 2.0 |

| Grammage | GSM | 340 +/- 5% |

Specifications for PVDC coated PVC Film-40 GSM

| Property | Unit | Standard Specifications |

|---|---|---|

| Total GSM | GSM | 354.25 to 405.625 |

| GSM of PVDC Coating | GSM | 36 to 46 |

| Adhesion of PVDC with Substrate | - | To Comply |

| Dimensional Stability - Longitudinal | % | -8 to 0 |

| Dimensional Stability - Transverse | % | 0 to 4 |

| Thickness of PVC film | GSM | 323 to 357 |

| Inner Diameter of core | mm | 75.5 to 76.5 |

| *WVTR @ 38 deg. Cel.,90% RH | gms/(Sq.m.day) | 0.6 to 0.65 |

| Toxicity | - | To comply as per USP-37 |

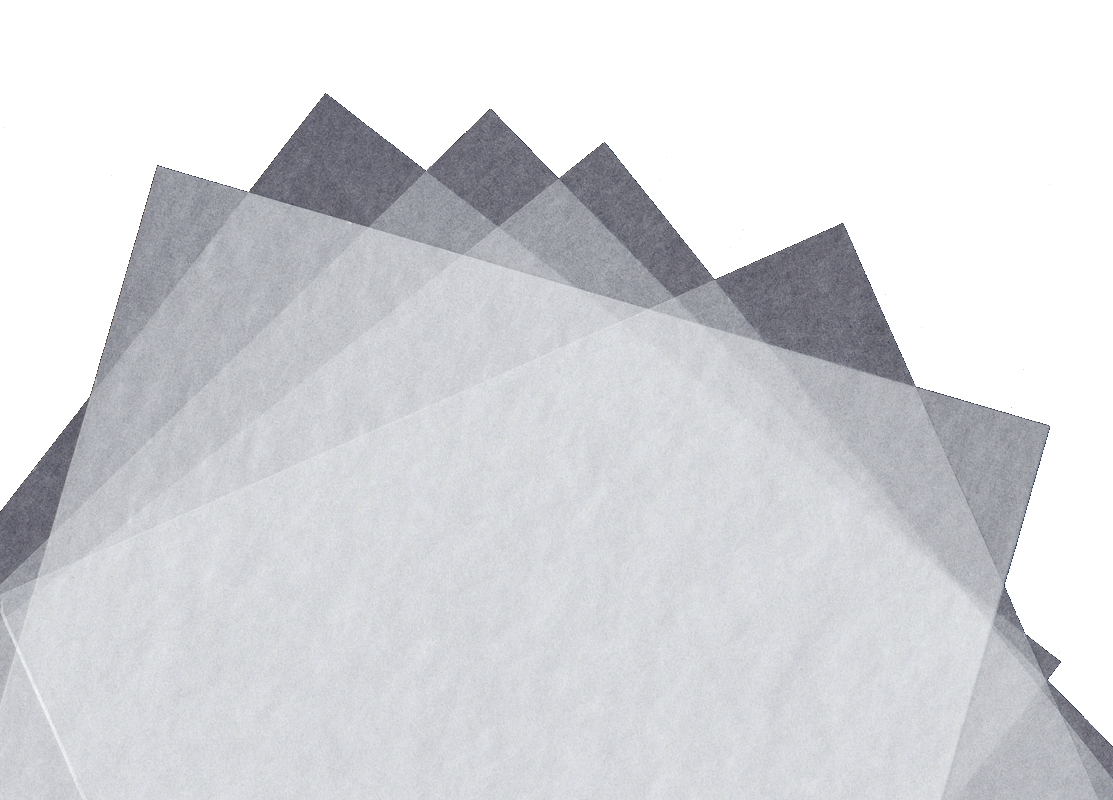

GLASSINE PAPER (vmch coated)

Specifications for H S Coated Glassine Paper

| Test Parameter | Unit | Standard Specifications |

|---|---|---|

| Reel Diameter | mm | 500 +/- 10 mm |

| Core ID | mm | 75/76 mm |

| Reel Width | mm | As required by customer |

| Unwinding Direction | - | As per approved specimen |

| Cleanliness | - | Clean, Free from excessive or objection odour |

| Total Weight | GSM | 43.20-44.30 |

| Raw Paper Weight | GSM | 38.00-42.00 |

| VMCH | GSM | 3.00-3.50 |

| Paper Finish | - | Generally free from Pin-holes, Specks Crease & other Blemishes |

GLASS BOTTLES, GLASS VIALS & AMPOULES

HDPE BOTTLES & CLOSURES (Threaded & child resistent)

Quality Promise

We procure coated & laminated foils, PVC Films, PVC/PVDC films, and other aforesaid products from standard ISO certified / GMP certified vendors who possess DMF numbers. This ensures our quality consciousness for quality supplies to our customers.